The small-scale plant was build specifically to allow the benefits of the larger test line to be replicated for small tank volumes.

Some of the possibilities and fields of application of the small-scale plating line:

- Special coating (layers of noble metals, alloys or dispersion layers)

- Small-volume runs, sensitive small components

- Drum coating processes

- Test coatings for physical and optical inspections

- Low-cost coating of individual workpieces

- Analysis of long-term behaviours of tank additives in connection with low part volumes

Application

One typical application of the small-part plating line is the electroless coating of accessories made of aluminium for very small devices whose dimensions are in the range of one millimetre to only a few centimetres. Due to the small size and the need for individual treatment of the accessories, coating in larger installations would be uneconomical.

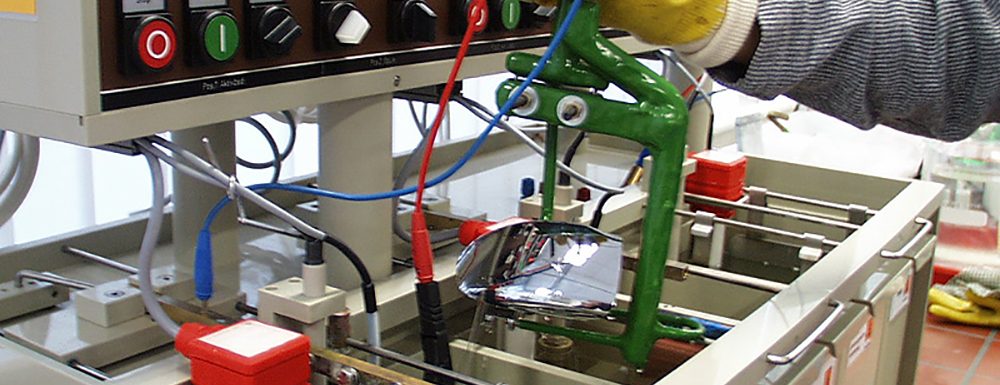

Installation for electrochemical deposition processes (up to 20 A)

To perform pulse plating at laboratory level, the small-scale plating line is equipped with a pulse rectifier with an output of 20 amps at 20 volts (anodic and cathodic). Where greater outputs are required and for test purposes on the test line, we are in close contact with the manufacturers of pulse rectifiers and can make rectifiers available at short notice and at reasonable cost with all the required parameters. Where the client so wishes, the rectifier used for the tests can be taken over by the client to minimise deviations between the test results on the test line and in subsequent production.

Deutsch

Deutsch

English

English