A crucial service offered by IGOS is the examination of damage caused by accidents followed by production of an expert opinion on the surface issues involved that can be used in a Court of Law.

These may include:

a) Corrosion problems, with or without coatings

b) Adhesion problems with metallic and organic coatings

c) Fractures resulting from hydrogen embrittlement

d) Poor quality appearance or the presence of surface defects

e) Rupture surface analyses

The numerous damage inspection methods at our disposal are selected by us specifically to provide the best possible explanation of the cause of the damage with the least material expense and in the shortest possible time.

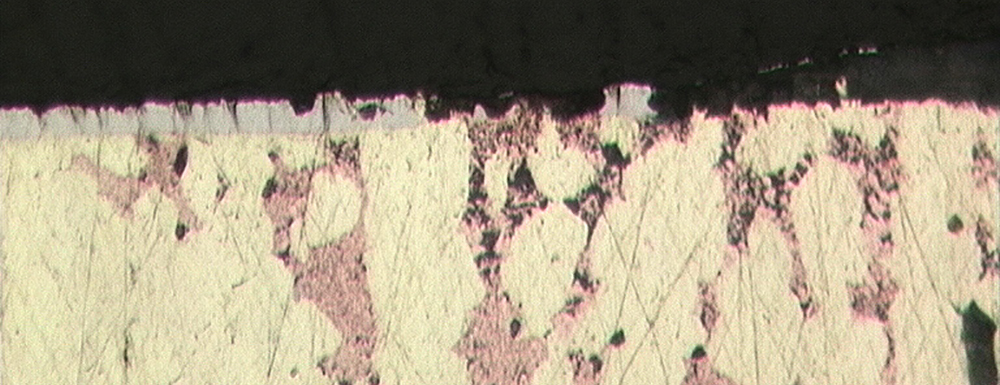

a) Analysis of a corroded water connection

Results: corrosive attack on the nickel or chromium coating and the substrate.

Image: Corrosive attack on the coating and substrate; product of corrosion in the vicinity of the nickel layer and localised corrosion and de-zincification of the brass.

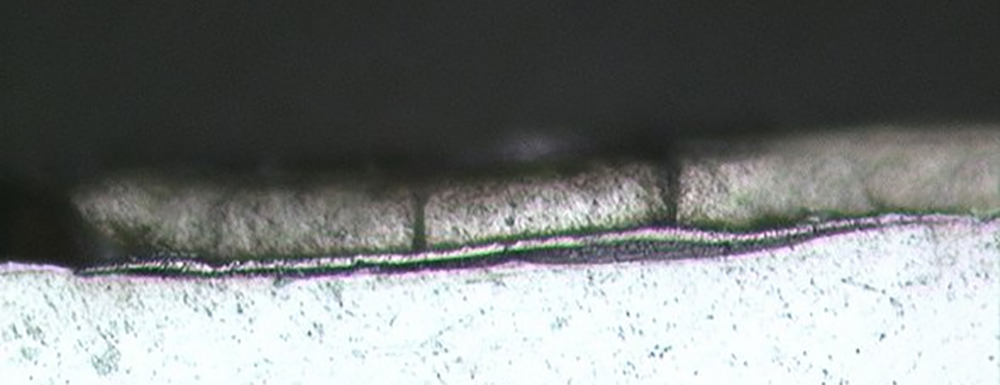

b) Adhesion problems

Image: Adhesion problems on zinc-plated sheet steel due to poor surface condition of the substrate

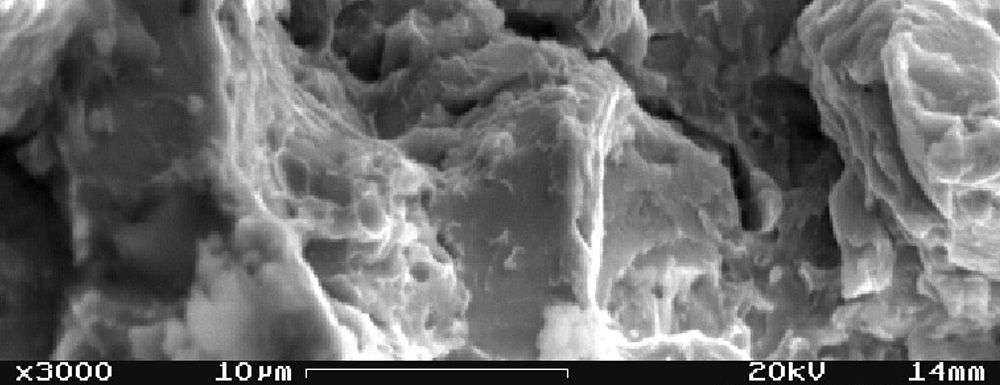

c) Hydrogen embrittlement during zinc-plating of hardened steel

Hydrogen gassing is a key issue when zinc-plating hardened steel. Electrochemical zinc-plating in alkaline and cyanide electrolytes is performed with low current efficiency and is accompanied by the production of considerable quantities of hydrogen. Due to the very small radius of hydrogen atoms, they are able to penetrate easily into cracks and pores in the substrate and cause the grain boundaries to become brittle. Hydrogen embrittlement can result in changes to the physical properties of the substrate, such as a reduction in ductility, elastic limit, elongation, constriction, flexural strength etc.

IT is possible to verify these effects using a scanning electron microscope (SEM) analysis of a ruptured surface.

Example: Analysis of a zinc-plated, yellow chromated window screw after breakage

Image: Surface of breakage with clearly visible grain boundary embrittlement and the "fish-eye" effect so typical of hydrogen embrittlement

Deutsch

Deutsch

English

English