To assess resistance to corrosion in practice, we require data about the corrosion behaviour of the materials and the effectiveness of anti-corrosion protection measures, such as coatings and lacquers, in quantifiable, controlled, real-world corrosive conditions.

Quick corrosion tests can hardly be expected to determine the lifetime of a material in a real environment.

Very often, corrosion tests of this kind are carried out as quality inspections of materials, coatings and lacquers, i.e. as end-of-line quality controls.

However, it is often possible to draw certain conclusions about the anticipated lifetime from empirical examinations.

The closer the practical testing environment comes to the real-life conditions, the greater the value of the corrosion test results and, conversely, the more they deviate from one another, the greater the difference may be, in particular, if a change in the type of corrosion results in a change in the way it acts.

Salt spray testing

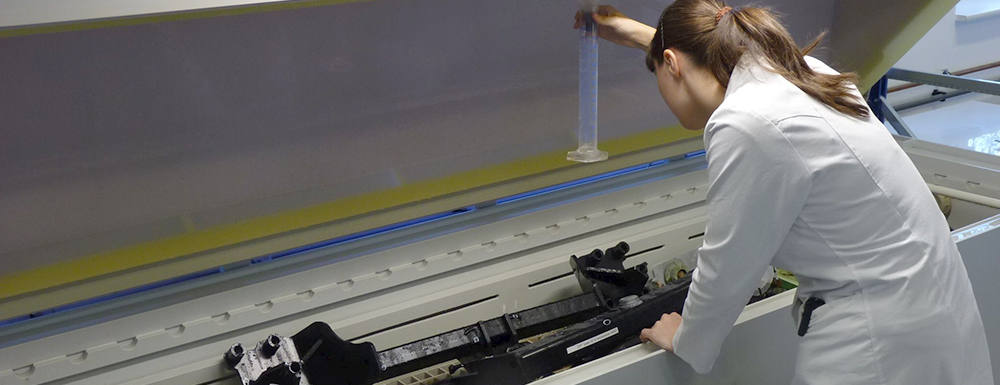

We analyse reliably and safely using state-of-the-art equipment backed up by many years' experience.

Read more

Condensation testing

These supply information on the detection of defects in the corrosion protection on the samples in moist environments.

Read more

Climate simulation testing

On the one hand, these tests allow us to assess the behaviour of components in a range of geographical locations of our planet. On the other hand, lifecycles (seasons) can be simulated.

Read more

Special tests

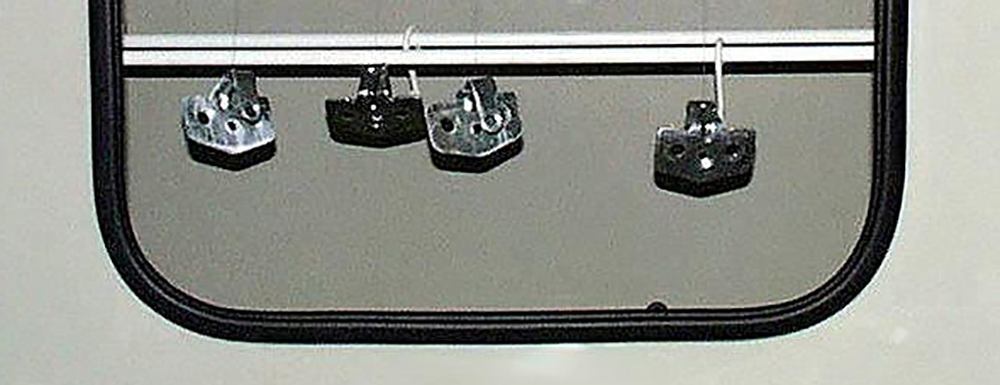

As a result of the state-of-the-art equipment at the Institute, we are in a position to perform special tests to determine corrosion resistance levels, such as measuring the element current density between plastics and aluminium.

Read more

Deutsch

Deutsch

English

English