IGOS increases testing capacities

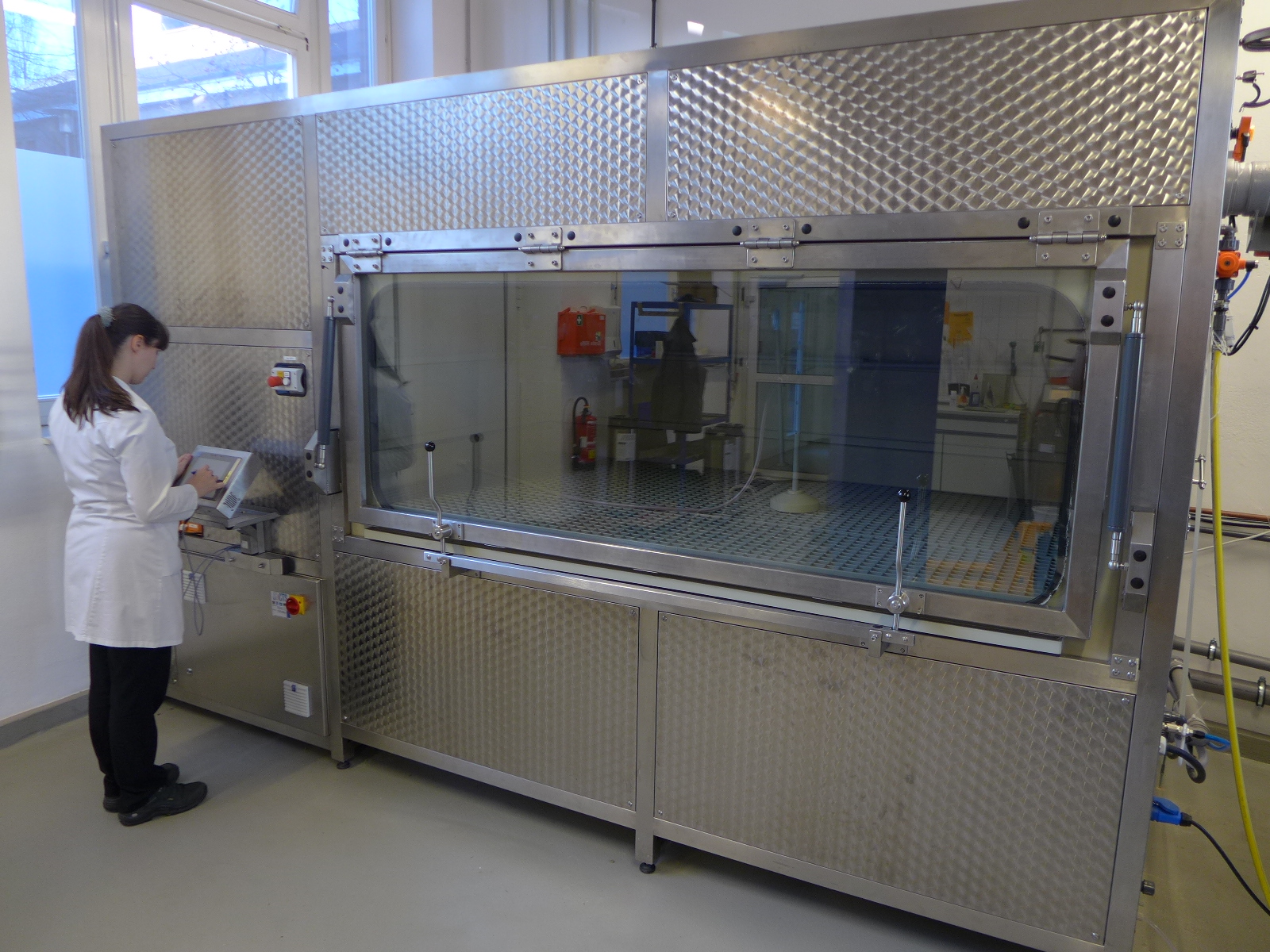

At IGOS (Institut für Galvano- und Oberflächentechnik Solingen GmbH & Co. KG) the possibilities in the field of corrosion testing have been decisively expanded. A further corrosion test chamber was put into operation for this purpose. With a test volume of 3.4 m³, it is now also possible to test components with a length of op to 2.5 m and a maximum weight of 500 kg. A big advantage of the test chamber is that it can be approached with a lift truck. This means that even heavy and bulky patterns can easily be introduced into the chamber.

With the new test chamber, IGOS, which offers its customers layer and damage analyses, complex corrosion tests, but also electroplating technology and chemical analyses, is reacting to the growing requirements of its customers from a wide variety of industrial sectors. In the modern corrosion laboratory in Solingen a large number of accredited corrosion tests (e. g. combination tests or varios climate change tests with various modification possibilities) can be carried out on an area of approx. 200 m². With the new test chamber, this is now also possible for larger components or entire assemblies.

The test chamber is suitable for conducting salt spray tests (e. g. DIN EN ISO 9227 NSS), condensation water tests (e. g. DIN EN ISO 6270-2) and various combination tests, such as the climate change test according to DIN EN ISO 11997-1 Cycle B (formerly: VDA 621-415). After installation of the chamber, several instrument settings were thoroughly checked and the suitability of the programmed corrosion test sequences was tested. The functional and corosivity test according to DIN EN ISO 9227 NSS was successfully completed, so that accredited tests can now be carried out. We can also respond to special customer requests and create individual programs.

Accredited partner of the industry

IGOS has been the supra-regional contact for industry in all questions of surface technology since 1993. Corrosion tests of various kinds have been carried out since 1997 and since 2006 the company has been accredited according to DIN EN ISO 17025. The accreditation certifies the competence of the DAkkS (German Accreditaion Company) to carry out corrosion tests as well as other test methods commonly used in surface technology.

Corrosion testing is one of the most important methods for monitoring the effectiveness of production control of materials with and without coatings. For some years now, independent laboratory tests have been increasingly requested or demanded in order to confirm self-tests and to certify the correctness of test results to business partners.

Deutsch

Deutsch

English

English