New corrosion testing centre at IGOS

Demands on coating systems are constantly increasing. The resistance of components to corrosion is a key indicator of the quality of an electrochemical coating.

Corrosive behaviour is dependent both on the quality of the substrate and the metallic and/or organic coating quality.

In order to emulate the many kinds of weathering and corrosion encountered in the real world, manufacturers, in particular those in the automotive industry, require ever more complex and demanding corrosion tests.

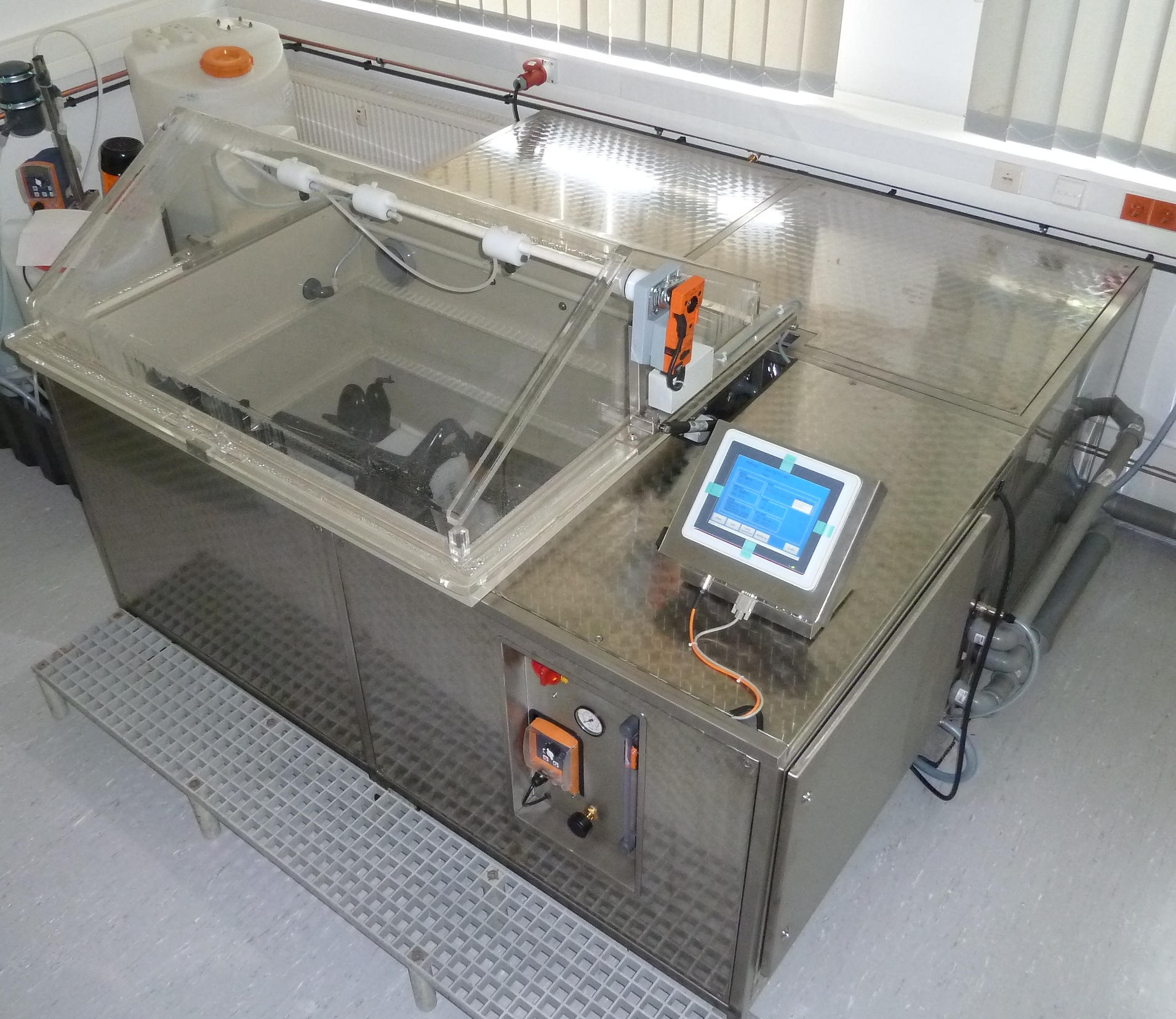

In our new corrosion testing centre we are now in a position, with immediate effect, to run all standard alternating atmosphere tests fully automatically.

With our new testing chamber, we can now offer you the following standard alternating atmosphere tests:

|

|

We will, of course, continue to provide all our usual corrosion testing services as listed below in tried-and-tested quality:

- All salt-spray testing procedures

(DIN EN ISO 9227, ASTM B117, some also available for heavy or over-sized parts) - All condensation water testing procedures

(DIN EN ISO 6270-2, DIN 50018, DIN EN ISO 4541, DIN 50958) - Climatic simulation tests

(to BMW, VW, DBL etc.)

Deutsch

Deutsch

English

English